The medical industry continues to evolve with the introduction of advanced materials that improve patient care and medical device performance. One of the most significant innovations in this sector is high-strength medical steel. This specialized steel is essential for producing surgical instruments, implants, and various medical devices that require superior durability, precision, and corrosion resistance. As the demand for stronger and more reliable medical materials grows, manufacturers in Chicago are adopting new technologies and techniques to enhance the performance of high-strength medical steel.

With increasing medical advancements, hospitals and device manufacturers need materials that can withstand harsh sterilization processes and extended use. High-strength medical steel plays a crucial role in achieving these goals, offering enhanced strength and resistance to wear. In this guide, we will explore emerging trends in medical steel manufacturing and how they are shaping Chicago’s healthcare industry.

Key Innovations in High-Strength Medical Steel for Chicago’s Healthcare Sector

The future of medical steel involves cutting-edge developments that are designed to improve safety, longevity, and efficiency in healthcare applications. These innovations are transforming the way medical professionals and manufacturers approach surgical tools and medical implants.

Advanced Alloy Compositions for Enhanced Durability

New alloy compositions have led to improvements in the strength and flexibility of medical steel. Manufacturers are incorporating elements such as titanium and cobalt to create lightweight yet durable materials that enhance surgical performance. These advanced alloys offer superior resistance to corrosion, ensuring longer-lasting medical tools and implants that remain effective even after repeated use.

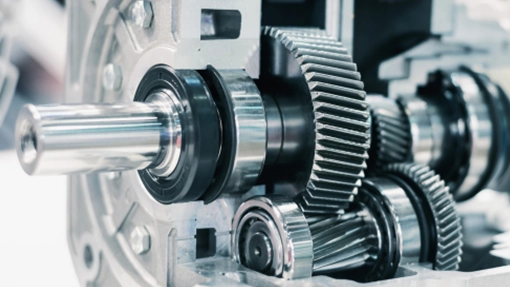

Precision Machining and Surface Treatments

The latest precision machining techniques allow for more intricate and refined medical tools. Advances in grinding and polishing methods help achieve ultra-smooth surfaces that reduce the risk of contamination and improve biocompatibility. Unique surface treatments such as passivation further enhance the corrosion resistance of medical steel, making it a preferred choice for surgical applications.

3D Printing and Custom Medical Components

The integration of 3D printing technology has revolutionized medical steel applications. Chicago’s healthcare industry is seeing an increase in customized implants and prosthetics made from high-strength medical steel. This technology enables medical professionals to create patient-specific implants with enhanced precision, leading to better surgical outcomes and faster patient recovery times.

Sustainable and Sterile Manufacturing Processes

Sustainability is becoming a priority in the medical industry, and manufacturers are adopting eco-friendly production methods for high-strength medical steel. Advanced sterilization techniques ensure that medical tools and implants are free from contaminants, reducing the risk of infections. These cleaner manufacturing processes not only benefit patients but also contribute to environmental responsibility in healthcare production.

Conclusion

As the demand for stronger, more durable, and biocompatible medical materials increases, high-strength medical steel continues to drive innovation in Chicago’s healthcare industry. Advancements in alloy composition, precision machining, 3D printing, and sustainable manufacturing are revolutionizing the way medical tools and implants are produced. Hospitals, medical device manufacturers, and surgeons can benefit from these improvements, ensuring higher performance, longevity, and safety in medical applications.

For businesses looking for precision grinding and machining solutions for medical steel applications, Advance Grinding Services, Inc. in Bedford Park, IL, offers expertise in centerless grinding, bar chamfering, round bar polishing, and custom machining. Contact us today to learn how our services can enhance your medical manufacturing needs.

FAQs

What are the benefits of high-strength medical steel?

High-strength medical steel offers superior durability, corrosion resistance, and biocompatibility, making it ideal for surgical tools and implants.

How is high-strength medical steel used in the healthcare industry?

It is widely used for manufacturing surgical instruments, orthopaedic implants, dental tools, and custom prosthetics due to its strength and precision.

What advancements are improving medical steel production?

Innovations such as advanced alloy compositions, precision machining, 3D printing, and eco-friendly manufacturing processes are enhancing the quality and functionality of medical steel.

How does 3D printing impact the use of high-strength medical steel?

3D printing allows for customized implants and prosthetics tailored to individual patients, leading to better surgical outcomes and improved recovery times.

Where can I find high-quality high-strength medical steel in Chicago?

Advance Grinding Services, Inc. specializes in precision grinding and machining solutions for medical applications. Contact us to learn more about our services.