High-strength medical steel has become a crucial component in the advancement of modern healthcare, particularly in a city like Chicago, which is known for its innovative medical sector. The demand for high-performance, durable, and corrosion-resistant steel in the healthcare industry has led to significant advancements in medical device manufacturing, surgical instruments, and implants. Advance Grinding Services, Inc., based in Bedford Park, IL, plays an essential role in providing precision-ground bars and high-quality centerless grinding services to meet the stringent requirements of medical applications.

The Importance of High-Strength Medical Steel in Medical Advancements

Medical professionals rely on surgical instruments and implants that must withstand rigorous use while maintaining their integrity. High-strength medical steel offers exceptional durability, ensuring that tools and devices retain their performance over time. This material is used in various applications, including orthopedic implants, cardiovascular devices, and precision surgical instruments, which require consistent quality and high corrosion resistance.

The ability to maintain sharpness and structural integrity is essential for surgical instruments used in delicate procedures. Stainless steel grades such as 316L and 17-4 PH are commonly used in medical applications due to their biocompatibility and high resistance to body fluids and sterilization processes. By utilizing high-strength medical steel, manufacturers in Chicago can contribute to safer and more effective medical treatments.

How Precision Ground Bars Enhance Medical Steel Performance

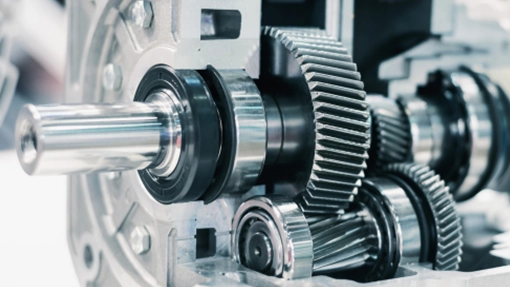

Precision ground bars serve as the foundation for high-performance medical steel products. Their uniformity, superior surface finish, and tight tolerances make them ideal for applications requiring exact specifications. The use of precision grinding ensures that each bar meets the precise requirements of medical manufacturers, enhancing the reliability and efficiency of medical components.

Advance Grinding Services, Inc. specializes in providing precision ground bars tailored to the healthcare industry. Their expertise in centerless grinding allows them to achieve ultra-fine surface finishes and tight diameter tolerances, critical for the production of medical devices. With advancements in medical technology, the need for high-quality steel components has never been greater, and precision grinding services ensure that each product meets the rigorous standards of the industry.

The Role of Chicago’s Medical Industry in Driving Steel Innovations

Chicago has long been at the forefront of medical research and innovation, with world-class hospitals, research institutions, and medical device manufacturers leading the charge. The increasing demand for high-strength medical steel has driven the need for advanced machining techniques, including bar chamfering, round bar polishing, and saw cutting. These processes help ensure that medical steel components meet the necessary standards for strength, precision, and performance.

Hospitals and medical device manufacturers in Chicago require a consistent supply of high-quality steel to support their research and treatment advancements. The collaboration between steel providers and healthcare innovators has led to significant improvements in the manufacturing of prosthetics, orthopedic implants, and specialized medical tools, benefiting patients and medical professionals alike.

Advance Grinding Services: A Trusted Supplier of Medical-Grade Steel

Advance Grinding Services, Inc. is a leading provider of high-strength medical steel in Chicago, offering a comprehensive range of precision grinding and machining services. Their commitment to quality and precision ensures that medical manufacturers receive steel components that meet the strictest industry standards. With services such as precision centerless grinding, bar chamfering, round bar polishing, saw cutting, bar straightening, and bar packaging, they provide customized solutions tailored to the healthcare sector.

By leveraging state-of-the-art technology and extensive industry expertise, Advance Grinding Services helps medical manufacturers produce high-quality instruments and implants that improve patient outcomes. Their precision-ground bars play a critical role in the production of durable and reliable medical devices, ensuring that healthcare providers have access to the best materials for their work.

Conclusion:

The demand for high-strength medical steel continues to grow as the medical industry advances, particularly in a city like Chicago, which is renowned for its healthcare innovations. The role of precision grinding and high-quality steel components in medical applications cannot be overstated. By ensuring that surgical instruments, implants, and other critical medical tools meet stringent quality standards, manufacturers can contribute to better patient care and medical advancements.

Advance Grinding Services, Inc. remains a trusted partner in supplying high-strength medical steel, providing manufacturers with precision-ground bars and superior machining services. Their dedication to excellence ensures that Chicago’s medical sector continues to have access to the highest quality materials for groundbreaking treatments and surgical innovations. For more information on sourcing high-strength medical steel, contact us.

FAQs

What makes high-strength medical steel essential for healthcare applications?

High-strength medical steel is crucial for healthcare applications due to its durability, corrosion resistance, and biocompatibility. It is used in surgical instruments, orthopedic implants, and medical devices that require precision and longevity.

How does precision grinding improve the quality of medical steel?

Precision grinding enhances the quality of medical steel by ensuring tight tolerances, superior surface finishes, and uniform dimensions. This process helps create reliable and high-performance medical components.

What industries benefit from high-strength medical steel?

The healthcare, biotechnology, and medical device manufacturing industries benefit the most from high-strength medical steel. It is used in everything from surgical tools and implants to specialized medical equipment.

What services does Advance Grinding Services, Inc. offer for medical steel manufacturers?

Advance Grinding Services provides precision centerless grinding, bar chamfering, round bar polishing, saw cutting, bar straightening, and bar packaging. These services ensure that manufacturers receive high-quality, precision-ground steel for their medical applications.

How can I request high-strength medical steel from Advance Grinding Services?

To learn more about high-strength medical steel or request machining services, visit Advance Grinding Services, Inc. today.