Aircraft-quality alloy steel bars are essential for high-performance applications that demand durability, strength, and precision. In Chicago’s industrial and aerospace sectors, sourcing the right supplier for these materials ensures reliability and consistency in manufacturing processes. Selecting a trusted supplier is crucial for businesses that rely on premium steel for aircraft components, landing gear, and structural applications. Advance Grinding Services, Inc., located in Bedford Park, IL, is a recognized provider of high-quality alloy steel bars, offering precision machining solutions tailored to the needs of various industries.

Understanding the Importance of Aircraft Quality Alloy Steel Bars

Aircraft components require materials that can withstand extreme conditions, including high stress, temperature variations, and corrosion. High-quality alloy steel bars provide the strength and resilience necessary for these applications, making them a preferred choice in aerospace manufacturing. The unique composition of aircraft-grade steel enhances its mechanical properties, ensuring long-lasting performance and safety.

The steel used in aircraft applications must meet strict industry standards to ensure consistency and quality. Manufacturers rely on precision ground bars with tight tolerances to meet engineering specifications. Advance Grinding Services specializes in centerless grinding and machining, producing steel bars that meet the highest standards of precision and surface finish.

Factors to Consider When Choosing a Supplier for Alloy Steel Bars

Selecting the right supplier for aircraft-quality alloy steel bars requires careful evaluation of several factors. The first consideration is the supplier’s industry experience and reputation. A well-established supplier like Advance Grinding Services has a proven track record of delivering high-quality steel bars to aerospace manufacturers and engineering firms in Chicago and beyond.

Material selection is another crucial factor. A reliable supplier should offer a variety of aircraft-grade alloys, including 4340, 300M, and other high-strength steel options. These materials are known for their exceptional toughness, fatigue resistance, and durability, making them ideal for aerospace applications. Advance Grinding Services provides a wide range of alloy steel bars, ensuring that clients receive materials tailored to their project requirements.

Precision and quality assurance plays a significant role in choosing a supplier. Aircraft components demand exact tolerances, and any deviation can impact performance and safety. Suppliers must implement strict quality control processes to guarantee consistent dimensions and surface finishes. Advance Grinding Services utilizes state-of-the-art machining techniques, including bar chamfering, round bar polishing, and custom machining, to meet the highest industry standards.

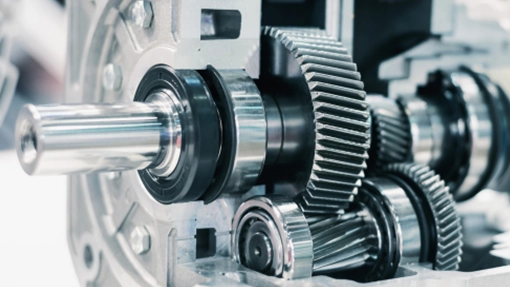

The Role of Precision Grinding in Aircraft Steel Bars

Precision grinding is a critical process in the production of aircraft-quality alloy steel bars. This technique ensures that steel bars achieve uniform dimensions, smooth finishes, and tight tolerances. By eliminating imperfections and enhancing surface integrity, precision grinding enhances the strength and reliability of steel components used in aviation.

Manufacturers depend on centerless grinding to achieve high-precision results. Advance Grinding Services specializes in precision grinding services that produce steel bars with excellent dimensional accuracy. Their expertise in round bar straightening and saw cutting further enhances the quality of materials used in aerospace applications.

Why Advance Grinding Services is the Preferred Supplier in Chicago

Advance Grinding Services, Inc. has built a reputation as a leading supplier of aircraft-quality alloy steel bars in Chicago. Their commitment to precision, quality, and customer satisfaction sets them apart in the industry. With a comprehensive range of machining capabilities, they provide high-performance steel solutions tailored to the specific needs of aerospace manufacturers.

Their facility in Bedford Park, IL, is equipped with advanced technology to produce precision ground bars that meet the stringent requirements of aircraft applications. From bar packaging to custom machining, Advance Grinding Services ensures that every steel component meets the highest standards of reliability and performance.

Conclusion:

Choosing the right supplier for aircraft-quality alloy steel bars is a critical decision for aerospace manufacturers and engineering firms. High-strength, precision-machined steel is essential for producing components that meet the rigorous demands of aviation. Advance Grinding Services, Inc. offers industry-leading expertise in precision grinding and machining, making them the go-to supplier for aerospace-grade steel in Chicago.

For businesses seeking reliable alloy steel bars for aircraft applications, Advance Grinding Services provides top-tier materials and machining solutions. Their dedication to quality ensures that every component meets exact specifications, contributing to the safety and efficiency of aerospace engineering. To learn more about sourcing high-quality aircraft alloy steel bars, contact Advance Grinding Services, Inc..

FAQs

What makes aircraft-quality alloy steel bars different from standard steel bars?

Aircraft quality alloy steel bars are engineered to withstand extreme conditions, offering superior strength, fatigue resistance, and corrosion protection. They meet stringent industry standards to ensure safety and durability in aerospace applications.

Why is precision grinding important in aerospace steel manufacturing?

Precision grinding ensures that steel bars achieve exact dimensions, smooth finishes, and tight tolerances. This process enhances the performance and reliability of aerospace components, making it a crucial step in aircraft manufacturing.

What types of aircraft-grade alloy steel are commonly used?

Common aircraft-grade alloys include 4340, 300M, and other high-strength steels known for their durability, toughness, and resistance to fatigue. These materials are essential for landing gear, structural components, and high-stress applications.

How does Advance Grinding Services ensure quality in aircraft steel bars?

Advance Grinding Services employs strict quality control measures, including precision centerless grinding, bar chamfering, and round bar polishing. Their commitment to accuracy ensures that each steel bar meets aerospace industry standards.

How can I request aircraft-quality alloy steel bars from Advance Grinding Services?

To request high-strength alloy steel bars for aerospace applications, visit Advance Grinding Services, Inc. today.