When it comes to precision manufacturing, accuracy is everything. Chicago’s industries, from aerospace to automotive, rely on high-quality materials that meet the strictest tolerances. The key to achieving such precision lies in centerless grinding services. Unlike traditional grinding methods that require clamping, centerless grinding eliminates the need for a fixed center point, allowing for continuous, highly efficient processing.

Advance Grinding Services, Inc., located in Bedford Park, IL, specializes in providing precision-ground bars and machining solutions that ensure optimal performance. With expertise in bar chamfering, round bar polishing, saw cutting, and custom machining, they play a vital role in supporting the region’s manufacturing sector.

Why Centerless Grinding is Essential for Precision Manufacturing

Manufacturers need materials with perfect roundness, tight tolerances, and smooth finishes to ensure the best performance. Centerless grinding services have become the preferred method for achieving this level of precision. By removing material with unparalleled accuracy, this grinding technique enhances the durability and functionality of metal bars and components.

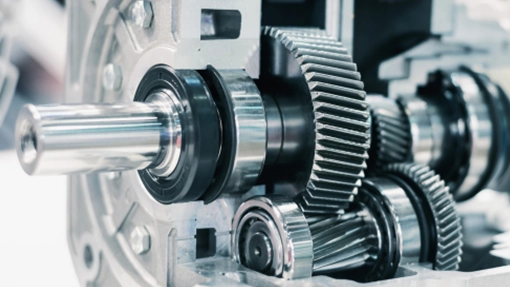

How Centerless Grinding Works

The centerless grinding process is unique in its ability to produce perfectly round and smooth materials without the need for clamping. Instead, the workpiece is placed between a grinding wheel and a regulating wheel, while a work rest blade supports it throughout the process. The grinding wheel performs the material removal, while the regulating wheel controls the speed and feed rate. This setup allows for continuous production, making it a highly efficient method for machining precision parts.

The two main types of centerless grinding include through-feed and in-feed grinding. Through-feed grinding is ideal for long, cylindrical workpieces that require a consistent diameter, while in-feed grinding is used for more complex shapes that need targeted precision. By choosing the right grinding method, manufacturers can ensure superior quality and efficiency in their production processes.

Chicago’s Leading Industries Depend on Centerless Grinding

Precision is crucial across many industries, and centerless grinding services have become a fundamental part of manufacturing in Chicago. Aerospace companies require flawlessly machined parts for jet engines and landing gear components, where even the smallest deviation can impact performance. Automotive manufacturers depend on precision ground shafts, fuel system parts, and transmission components to ensure smooth operation and longevity.

Medical device manufacturers also benefit from centerless grinding by producing surgical instruments, orthopedic implants, and other critical components with micron-level precision. The ability to achieve smooth finishes and exact dimensions ensures that these devices meet strict regulatory standards. By partnering with a trusted centerless grinding provider, these industries can maintain the high quality and reliability their customers expect.

Advance Grinding Services: A Leader in Precision Machining

Advance Grinding Services, Inc. has established itself as a leading provider of centerless grinding services in Chicago. Their expertise in precision machining allows them to deliver high-quality ground bars that meet the demands of various industries. With services ranging from bar chamfering and round bar polishing to saw cutting and custom machining, they provide comprehensive solutions tailored to each client’s needs.

Their commitment to quality, efficiency, and innovation sets them apart in the industry. By using advanced grinding techniques and state-of-the-art equipment, they ensure that every component they produce meets the highest standards. Their ability to achieve tight tolerances with minimal material waste makes them the go-to partner for manufacturers seeking top-tier grinding solutions.

How Centerless Grinding Improves Efficiency and Quality

One of the most significant advantages of centerless grinding is its ability to produce flawless surface finishes. The absence of clamping eliminates the risk of workpiece deformation, resulting in uniform, high-precision components. This is particularly beneficial in applications where surface smoothness is critical for reducing friction, improving wear resistance, and enhancing aesthetic appeal.

The continuous nature of centerless grinding also makes it one of the fastest and most efficient machining processes available. By eliminating the need for workpiece clamping and repositioning, manufacturers can significantly increase production speeds while reducing costs. Additionally, the process generates less material waste, making it an environmentally friendly and cost-effective option for large-scale production.

Conclusion:

As manufacturing technologies continue to evolve, the demand for high-precision components will only increase. Centerless grinding services will remain a cornerstone of industrial production, ensuring that manufacturers can achieve the quality and efficiency required for modern applications. In a competitive market, companies that invest in precision grinding will gain a significant edge, producing materials that meet the highest standards of accuracy and performance.

Advance Grinding Services, Inc. is committed to providing cutting-edge grinding solutions that help businesses succeed. Their expertise in centerless grinding ensures that manufacturers in Chicago and beyond have access to the highest quality materials for their operations. By partnering with a trusted provider, companies can confidently produce components that stand the test of time.

For more information about centerless grinding solutions, contact us.

FAQs

What is centerless grinding?

Centerless grinding is a machining process that removes material from cylindrical workpieces without requiring a fixed center point. This allows for continuous, high-precision grinding with excellent surface finishes.

How does centerless grinding differ from traditional grinding?

Unlike traditional grinding, which requires workpieces to be clamped in place, centerless grinding holds the material between a grinding wheel and a regulating wheel. This eliminates setup time, reduces material waste, and increases production efficiency.

Which industries benefit from centerless grinding services?

Aerospace, automotive, and medical device manufacturers rely on centerless grinding to produce precision components. The process ensures tight tolerances, superior surface finishes, and high-quality results.

Why should manufacturers choose Advance Grinding Services?

Advance Grinding Services provides expert precision grinding solutions tailored to the needs of various industries. Their advanced techniques, high-quality materials, and commitment to efficiency make them a trusted partner for manufacturers seeking the best in centerless grinding.

How can I request centerless grinding services?

To learn more about available grinding solutions or request services, visit Advance Grinding Services, Inc.