Manufacturers in Chicago’s automotive and aerospace industries are constantly seeking ways to enhance performance, precision, and durability. One crucial material that plays a significant role in these sectors is bearing shaft quality bars. These bars offer exceptional straightness, surface finish, and dimensional accuracy, making them ideal for high-performance applications. As technology advances, innovations in manufacturing processes have further improved the reliability and functionality of these bars, helping industries maintain efficiency and quality.

Companies in Chicago rely on bearing shaft quality bars for their consistency and mechanical strength. Whether used in high-speed engines, industrial machinery, or precision aerospace components, these bars are essential for reducing wear and tear while improving operational stability. In this guide, we’ll explore key innovations in bearing shaft quality bars and how they benefit modern manufacturing.

Advancements in Bearing Shaft Quality Bars for Chicago’s Industries

As manufacturing technology evolves, bearing shaft quality bars have seen significant improvements in their material composition, processing techniques, and applications. These advancements allow manufacturers to meet stringent industry standards while enhancing overall product performance.

Improved Material Composition and Coating Technologies

One of the key innovations in bearing shaft quality bars is the development of advanced material compositions and protective coatings. Manufacturers now use high-strength alloys and corrosion-resistant finishes to extend the lifespan of these bars. Specialized coatings reduce friction, preventing premature wear in high-speed or high-pressure applications. These improvements make bearing shaft quality bars more reliable for industries that demand high-performance materials.

Enhanced Precision Grinding and Straightening Techniques

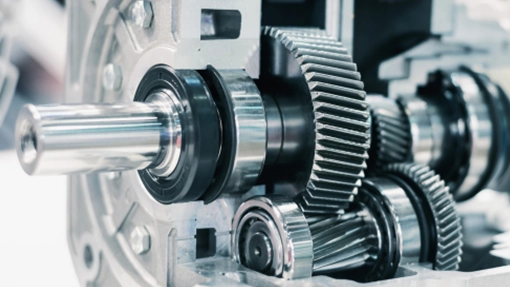

Precision is critical when producing bearing shaft quality bars, and advancements in grinding and straightening technologies have significantly improved their accuracy. Modern centerless grinding techniques provide superior surface finishes with tighter tolerances, ensuring consistent diameter measurements throughout the bar. Additionally, improved straightening processes help eliminate imperfections, allowing for seamless integration into high-precision machinery and automotive systems.

Increased Efficiency in Manufacturing Processes

Manufacturers in Chicago benefit from streamlined production processes that reduce lead times and improve cost efficiency. The adoption of automated machining and quality control systems ensures that each bar meets exact specifications. These advancements reduce material waste and increase production output, allowing businesses to keep up with growing industry demands without compromising on quality.

Applications of Bearing Shaft Quality Bars in Aerospace and Automotive Sectors

Chicago’s aerospace and automotive industries depend on bearing shaft quality bars for their durability and precision. In aerospace applications, these bars are used in landing gear, control systems, and critical structural components where high strength and minimal friction are required. In the automotive sector, they play a vital role in powertrain systems, steering mechanisms, and suspension components, ensuring smooth operation and longevity. As engineering requirements become more demanding, innovations in these bars continue to enhance performance and safety across both industries.

Conclusion

The advancements in bearing shaft quality bars have significantly impacted the aerospace and automotive sectors in Chicago. By improving material composition, grinding precision, and manufacturing efficiency, manufacturers can rely on these bars to deliver superior performance in high-stress environments. As technology continues to evolve, businesses that adopt these innovations will gain a competitive edge in producing high-quality, durable components.

For those looking for expertly manufactured bearing shaft quality bars, Advance Grinding Services, Inc. in Bedford Park, IL, offers precision centerless grinding, bar chamfering, round bar polishing, and custom machining services. Contact us today to learn more about our high-quality grinding solutions.

FAQs

What makes bearing shaft quality bars different from standard metal bars?

Bearing shaft quality bars undergo specialized grinding and straightening processes that enhance their surface finish, precision, and strength, making them ideal for high-performance applications.

How do coating technologies improve bearing shaft quality bars?

Advanced coatings reduce friction, prevent corrosion, and enhance wear resistance, ensuring a longer lifespan for bars used in demanding industries like aerospace and automotive.

Why are precision grinding techniques essential for bearing shaft quality bars?

Precision grinding ensures uniform diameter and smooth surface finishes, reducing friction and enhancing performance in critical mechanical systems.

Can bearing shaft quality bars be customized for specific applications?

Yes, manufacturers can customize these bars based on material composition, diameter, and coating requirements to suit specific industry needs.

Where can I find high-quality bearing shaft quality bars in Chicago?

Advance Grinding Services, Inc. specializes in providing high-precision grinding solutions for industries requiring top-tier bearing shaft quality bars. Contact us for more information on our products and services.